Australian industry is poised to benefit from satellite positioning technologies. In the coming weeks, Amira Global is hosting a series of webinars on the power of satellite positioning in resources. The first will be on the Satellite-Based Augmentation System (SBAS).

In the lead-up to these exciting webinars, Amira Global invited Project 412 CEO Paul Lucey to answer a few questions about satellite positioning in the resources sector, in particular SBAS. Paul has an extensive background in technology, innovation, and automation in the resources sector. He led a 3D spatial company in the United States before becoming involved in automation.

Paul believes the Australian resources industry is well positioned to take advantage of satellite positioning.

What is SBAS

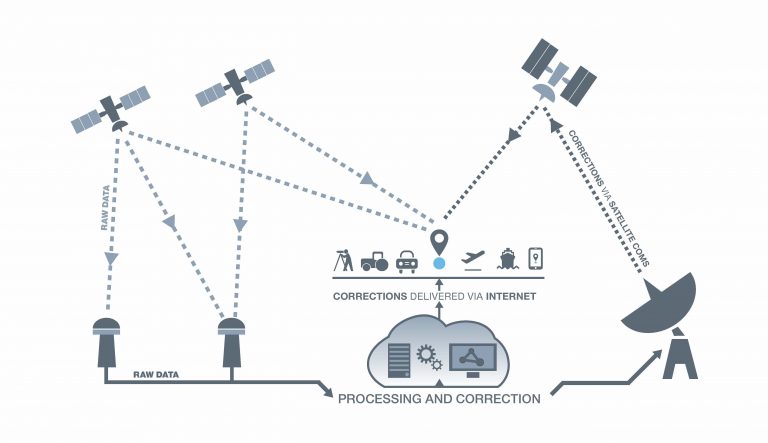

SBAS is currently used in the aviation industry to improve the accuracy, integrity and availability of Global Navigation Satellite System signals needed for vertical guidance. Using the calibration system, operators can pinpoint aircraft location to 10cm.

What do you think are the key challenges for the resources sector in positioning?

“The key challenges are cost, complexity, and the lack of adoption of mobile technology in the mining industry. Mobiles are seen as personal devices, rather than tools. However, when you have something like SBAS, which can give you 0.5m accuracy on your mobile phone, it makes measuring stockpiles and such so much easier. You can bring more data into your company, and more data means better decisions, and better decisions means more money.”

What is the role of spatial science in the resources sector, and what do you think is the maturity of this sector in this space?

“The way we manage spatial data in mining is probably some of the most mature of any sector in the world, simply because where the ore is of critical importance to us. Having worked outside the sector, I now recognise how advanced we are in what we do spatially. However, there are a lot of components outside of mining that could be of use from a spatial perspective.”

What research opportunities do you think lie ahead in the spatial sciences?

”Mining software is based on CAD based systems which served the industry well for the most part. With the LIDAR and cameras now more common on mobile pieces of equipment and drones and being used by mining companies, this kind of data is not easily digestible by CAD based systems. One the key issues here is that CAD based systems have challenges with textures mesh and large point clouds. Other industries without legacy software have more modern ways of dealing with this which includes the use of voxels for texture meshing on large data sets that these new instruments can collect.

“I think that is the next step for us. The amount of data coming in, and particularly the type of data, are not able to be readily used by the existing CAD-based systems.”

How is Australia positioned in this space compared to other jurisdictions?

“We are doing pretty well because we have an advanced mining ecosystem. A lot of the software is written in Australia, so I think we in the top spot to take advantage of the next step in the spatial evolution of mining.”

What can we learn from other sectors that would be of benefit to the resources sector?

“We need to be looking at what the automotive industry is doing with regards to standard practices. It has a lot of different software, but the basic data and process formats are the same. Mining seems to invent its own systems – which is one of its inherent challenges.”