Program Overview

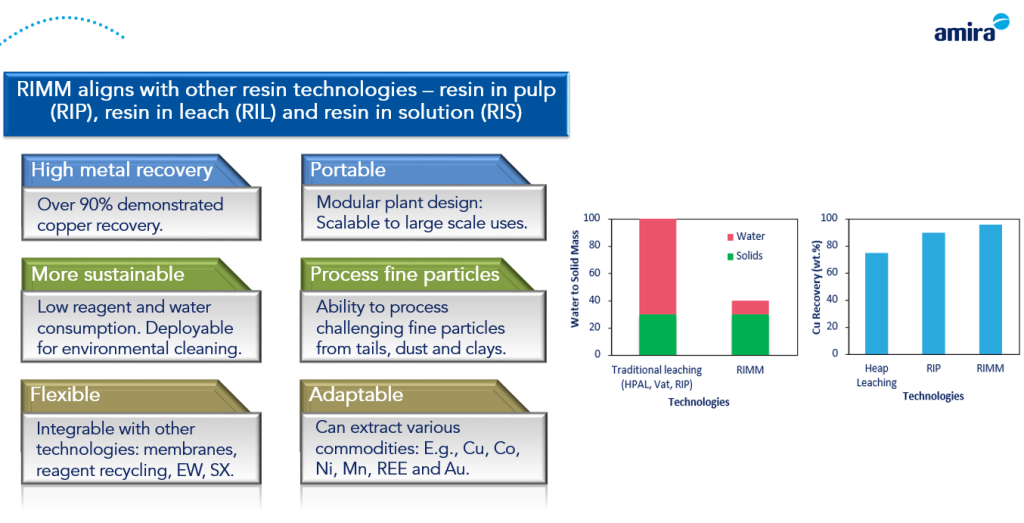

P1359B is an Amira mineral processing research project focused on advancing the Resin in Moist Mix (RIMM) process for the recovery of copper, cobalt, rare earth elements (REE), and other strategic metals from low-grade ores and mineral wastes. The RIMM technology, developed by InnovEco Australia and tested at the University of South Australia, has demonstrated high recovery efficiency combined with low water and reagent consumption.

The project aims to expand the current understanding of RIMM’s capability and applicability across a broader range of complex and currently uneconomic resources, including tailings, mine wastes, mine wastewater, and acid mine drainage (AMD). With potential for portable and modular plant configurations, RIMM offers a unique opportunity for small deposits, distributed resources, and environmentally focused rehabilitation and remediation applications.

Benefits

- Recovery of copper, cobalt, REE and other critical metals from low-grade ores and waste materials

- Access to a simple, low-water, and low-reagent processing technology with strong ESG credentials

- Potential for modular and portable processing solutions suitable for small or stranded resources

- Opportunities to integrate RIMM with complementary technologies to improve overall process economics

- Applicability to environmental remediation, tailings reprocessing, and mine site rehabilitation

- Development of practical flowsheets supported by laboratory and pilot-scale demonstration

Register Your Interest

The P1359B RIMM Process project is currently under development and open to sponsor participation.

For further information or to discuss involvement, please contact:

Redeemina Comfort Bonnah