Darren Mottolini

Chair – WA Surveying and Spatial Sciences Institute.

In today’s society, we all understand the importance of having accurate, complete and current data in almost everything we do. We see this in how we plan our day, allocate work tasks and measure output from a day’s activity. Culturally we are driven by having the right data for the right purpose, and when we don’t have this, it causes, delay, frustration and potentially leads to more serious outcomes such as safety issues.

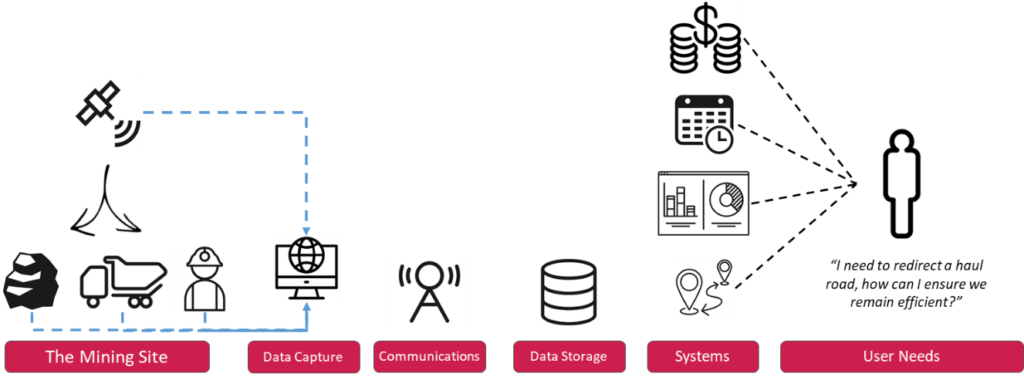

Over the past few years we have witnessed the integration of positioning sensors in a wide range of technologies providing insight of where an asset (whether people, equipment or infrastructure) is and when combined with data on how an asset is performing, it allows us to understand what is happening, where and potentially why. While positioning sensors provide us information on the location of our assets, people and infrastructure, simply knowing where something is does not answer the question “what happens next?”

This is what we call a knowledge gap. We are data rich yet without context of what the activity is, and the knowledge of what is required next we are forever interpreting the data, generally in separate systems.

It is potentially here, with accurate positioning that tracks key assets over time, that we find the opportunity to programmatically link it with the business operating context to bridge this knowledge gap. Let us break this down:

- GNSS, known as Global Navigation Satellite Systems gives us the ability to identify our location (in coordinates) on the Earth and is typically used to track people, equipment and embed location (X,Y,Z[1] coordinates) into the data collected allow it to be mapped with other data. These systems (more commonly referred to as GPS which is only one of a number of constellations of satellites) enable us to add important context to our data. For example:

A pit wall has a base, a height and a degree of angle. These pit walls extend over an area and when mapped with precise locations can be used to automatically calculate the volume of the excavated area, if a wall is within tolerance or at risk and provide the ability to compare change over time.

- Spatial, is typically identified as the GIS system that produces mapping information. These systems are in its simplest form a way to model and manage data, based on location, yet they enable a visual cue (i.e. a map) to where all your key information is. Depending on how you have structured the data model (i.e. its schema) the spatial data can be used to link to back end systems such as your asset information management (AIM) system.

- Operating Context: This could potentially be anything although for the purposes of this article, we refer to context as the operational business outcome desired and the rules and processes that manage how the outcome is achieved.

The challenge that faces many organisations is how to bridge this gap. Having accurate and precise position of key assets and people, and nowadays via micro sensors, tracking the mineral from block model to port can be contextualised through spatial systems. Machine Learning (ML) and Artificial Intelligence (AI) models are at the forefront of building operating context, to anticipate what may be required next based on the current and historical reference of data feeding into models. While excitement surrounds what ML and AI could deliver; accurate, consistent and complete data is required and this needs to be combined with human input of what are the tolerances, the expected behaviours and operating norms.

The spatial systems in place in many mining organisations are but a single system of many yet where we are able to increase the accuracy of our data, (helped through improved positioning to locate with certainty where anything is at a point in time) we can use this to visualise and improve integration across systems. This can then be improved by streamlining (automate) the integration of data across systems, which calls on codified business rules and processes helping us all to gain an insight into what happens next.

This is not a large leap, in fact using ‘spatial’ as a mechanism to bridge this knowledge gap is aimed at the small 1% improvement areas across the mining ecosystem. Automating the collection and integration of data with spatial context supports the next phase of anticipating what outcomes and impacts occur based on changing events.

In the future, spatial systems that understand the operating context can be used to automate the redesign of a haul road (supporting when a mine expands) or minimise the downtime between shifts though directing workers to their equipment in the most efficient way.

Capturing data with a location attribute is now commonplace with many off the shelf systems having a GNSS receiver that pinpoints the location of an asset. The next phase will be to capture the operating context and use this to improve our operations, and do this in small steps in different divisions that demonstrate how data and systems are purposed as a knowledge tool that provides the user insights supporting their activity and decision making, and not data just being a tool that you need to then interpret for your need.

Finally, if you are planning to invest in your data and technologies, do so with the outcome in mind. Who is the user? What decisions do they need to make?; this will ensure your investment provides you the confidence that the right decisions are being made.

For information on our upcoming webinar series Power of Positioning in Resources click here.

[1] XYZ: Latitude, Longitude and Height