Thanos Kotsiopoulos | University of Cape Town

Themes:

- Tailings repurposing that results in a step change in existing tailings volumes

- Step changes in the characterization, extraction and processing of material in the production of tailings volume

Title: Mitigating long-term liabilities of tailing storage facilities through integrated waste management

Research team:

Offering for sponsors:

The project is a low-cost solution to managing waste, mine closure and preventing acid mine drainage.

Summary:

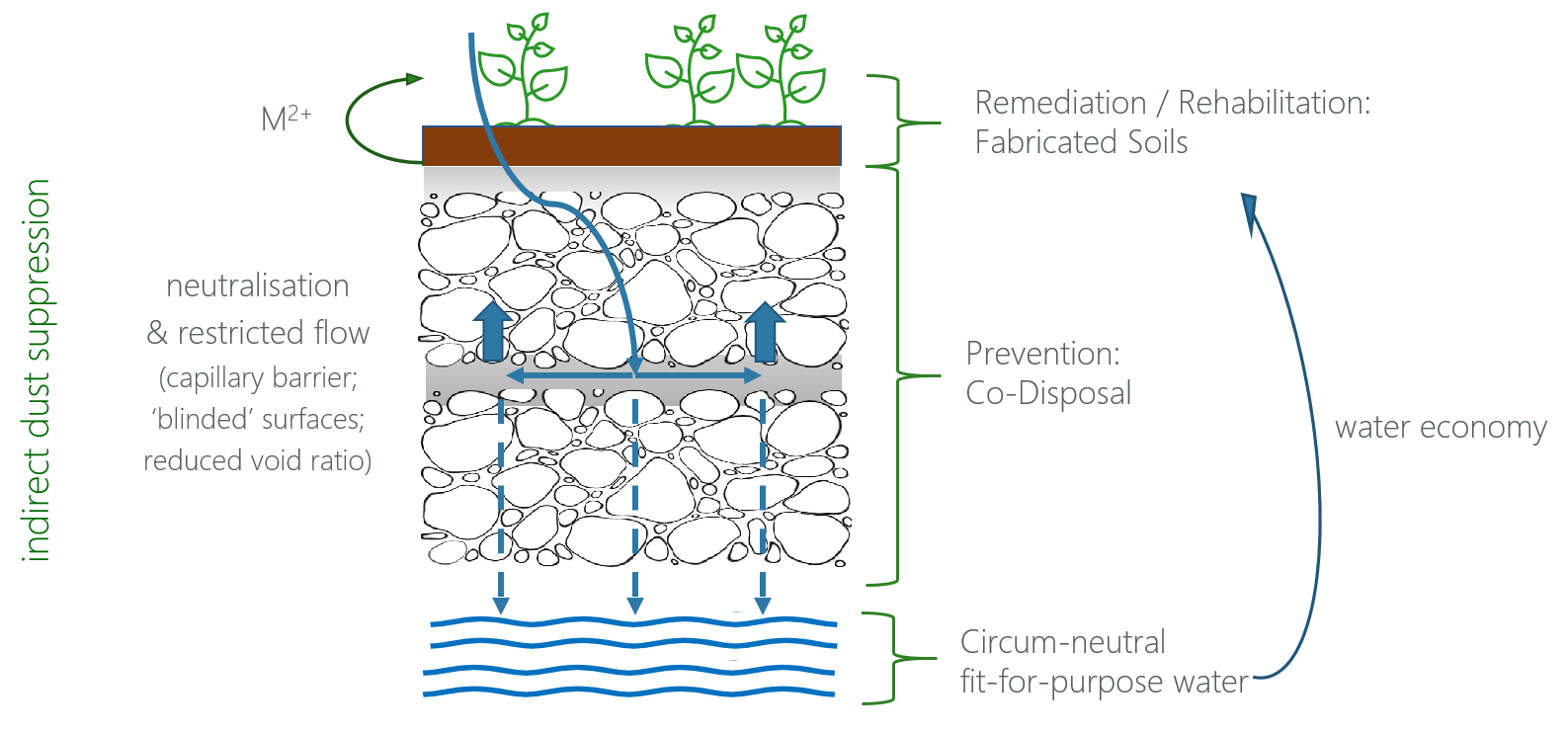

As water and arable land becomes increasingly scarce with ever-growing global populations, it is critical that we maintain water quality to sustain livelihoods, ecosystems and local economies. For countries that actively extract mineral resources, the negative impacts of mining may be long lasting as mine wastes continue to accumulate in risk-bound storage facilities. In this project we seek to reduce associated risks by recycling and repurposing these materials to prevent the onset of acid rock drainage (ARD) while simultaneously restoring mined areas to its previous arable state. Using sustainable practices, the principle of waste minimization is used together with industrial ecology for the re-purposing of waste materials from conventional mineral processing operations. Combined co-disposal and soil fabrication techniques will be used to develop an integrated prevention and rehabilitation strategy that will result in protocols for cleaner and less wasteful mining operations.

The fabricated soil can support plants with hyperaccumulators initially rendering the soils ready for agriculture and grazing lands.

Benefit to industry:

Economic

- opportunities to decrease or even eliminate the environmental liabilities of mine waste storage facilities

- facilitate the development and implementation of responsible approaches to mine waste management to avoid associated long-term environmental degradation and inter-generational burdens that this places on society

- reduce the significant remediation costs being incurred by both industry and government through the need to treat socio-environmental burdens created through poorly managed mine waste

- offer the potential to derive added value from already mined material.

Recordings of each submission are available to Members only. Please click on the link below to request access to the recordings and nomination form.