Sibel Pamukcu | Lehigh University | Priscilla Nelson | Colorado School of Mines

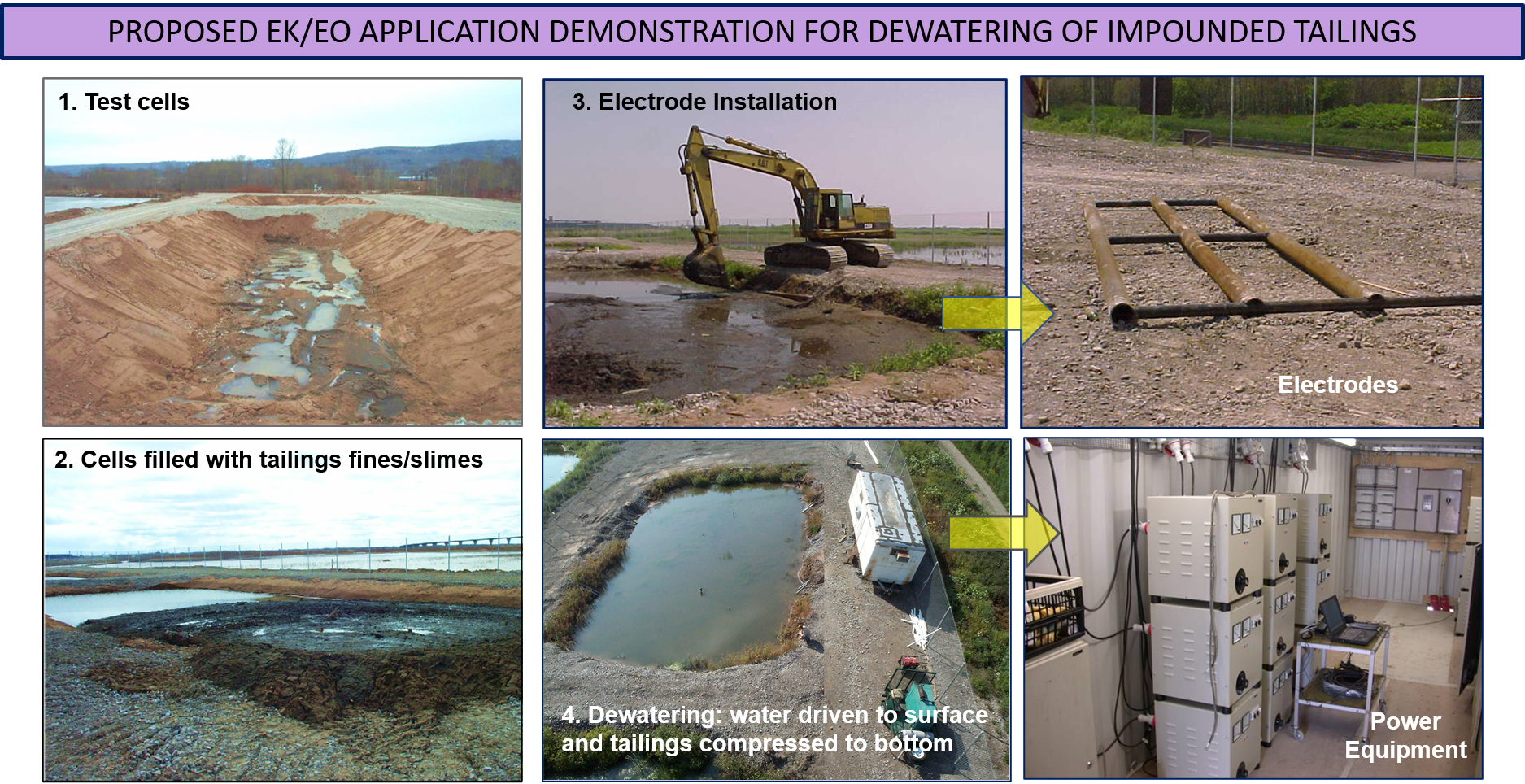

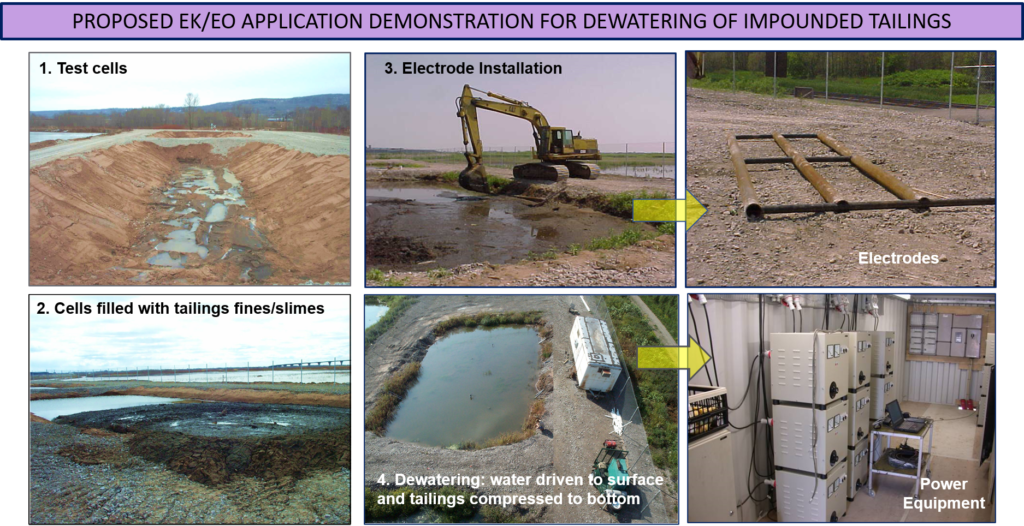

Theme: Avoiding catastrophic failure through water and water pressure control

Title: Sustainable EK/EO for Water Management and Resource Recovery from Tailings

Project team:

- Lehigh University

- Colorado School of Mines

- University of Minnesota

- Industrial consultancy

Offering to sponsors

The project offers proven technology to rapidly control and manage water in tailings without high CAPEX.

Project summary:

The project uses Electro-Kinetics/Electro-Osmosis (EK/EO) to dewater placed tailings (embankment or impoundment). EK/EO involves the application of direct current through electrodes installed in tailings materials, driving water flow out of the materials. The well-known technique has been successfully applied to dewater high water content dredged materials and slurries and will work best in fine grained materials.

EK/EO can be applied to manage water pressure within large masses. By integrating the electrodes with a sensor network, mine sites will be able to ‘surgically’ target zones in which porewater pressures are indicated to be increasing, rapidly reducing pressures as water is driven to a drainage anode. EK/EO can also be used in conjunction with Electro-Dialysis (ED) and ion exchange membranes to remove and recover metals, REEs and other species from seepage and impoundment water.

Benefit to industry:

Environmental

- By rapidly dewatering slimes, EK/EO technologies will enable industry recover process water efficiently.

Safety

- EK/EO, by speeding consolidation of impounded slimes and by targeted reduction in embankment water pressures greatly reduces the potential for catastrophic failure.

Economic

- EK/EO can be applied to recover critical and heavy metals which had been dissolved in impoundment and seepage water.

Recordings of each submission are available to Members Only. Please click on the link below to request access to the recordings and nomination form.