Richard Alorro | Curtin University

Themes:

- Tailings repurposing that results in a step change in existing tailings volumes

- Step changes in the characterization, extraction and processing of material in the production of tailings volume

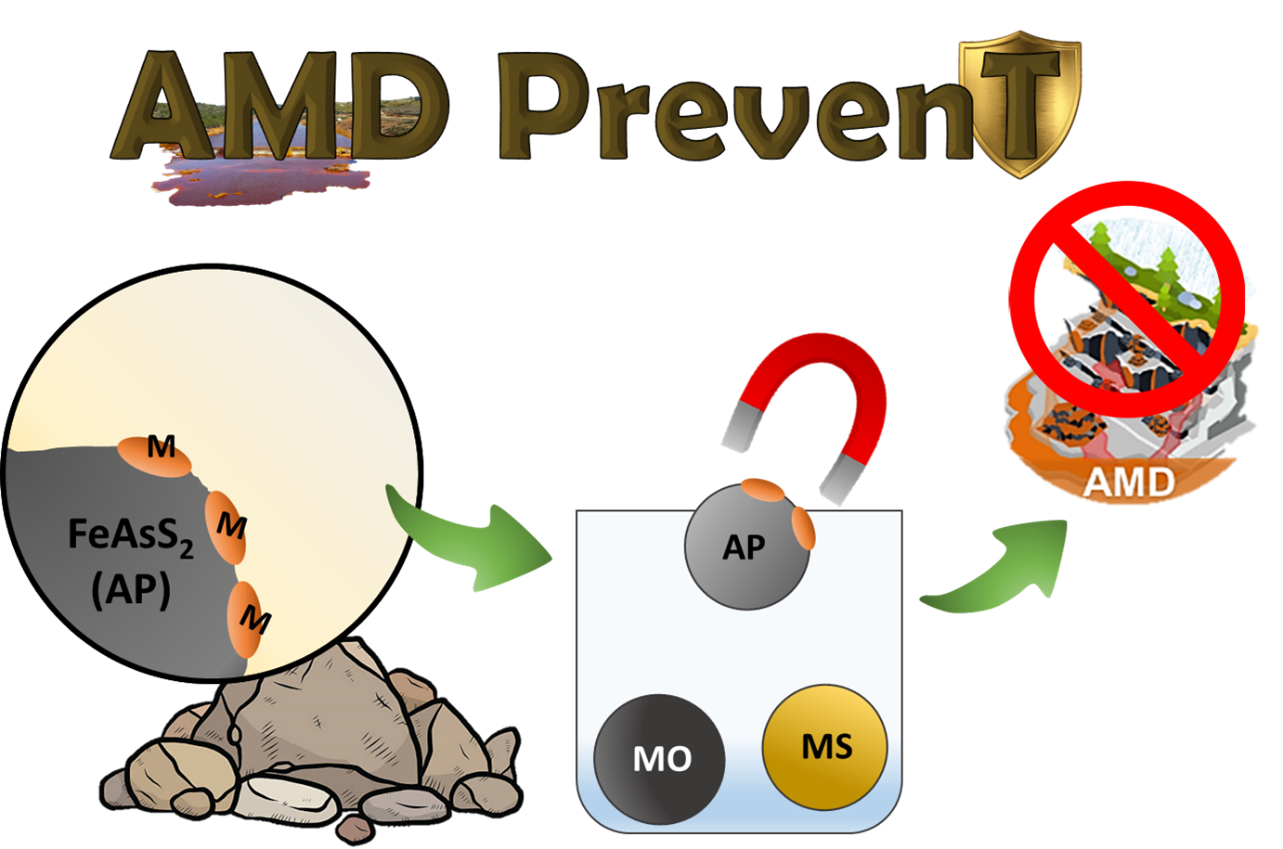

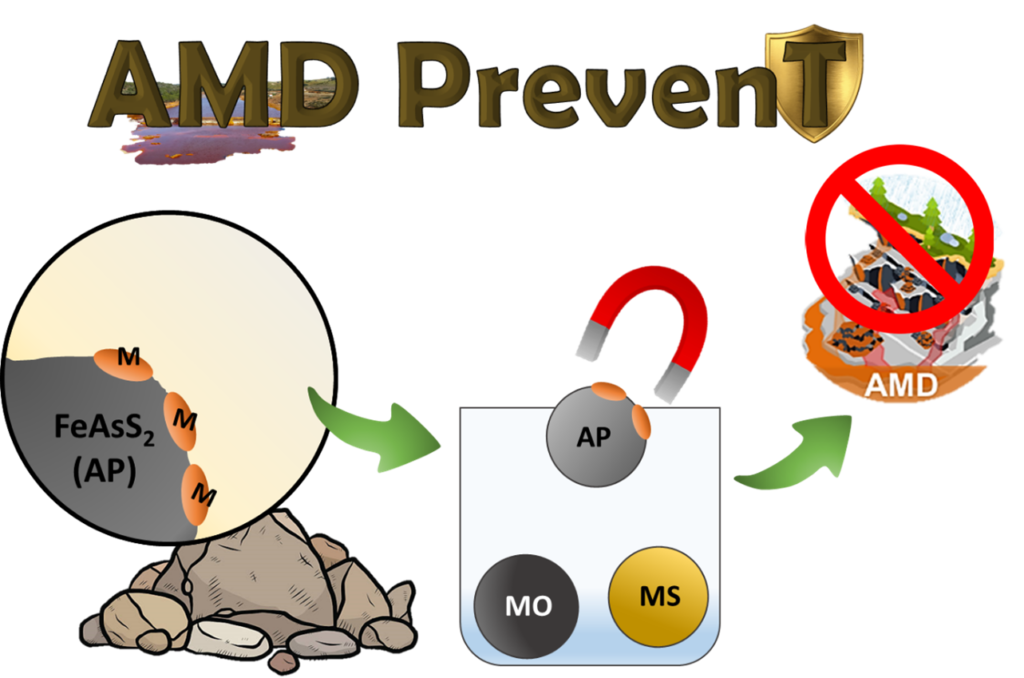

Project title: AMD PrevenT: Innovative Strategies for Sustainable Management of Mine Tailings and Prevention and Treatment of Acid Mine Drainage

Partners:

- Curtin University – WA School of Mines

- University of New South Wales

- Korea Maritime and Ocean University

- Hokkaido University

Offering to sponsors:

The project aims to reduce the expense of treatment and environmental/social risk of acid mine drainage (AMD) by removing arsenopyrites and other acid-forming sulphide minerals during processing or reprocessing, and repurposing alkaline-generating components of tailings for neutralization of existing areas of AMD concern.

Summary:

In terms of prevention, the project has two approaches. The first involves selectively removing arsenopyrite and other acid-forming sulphides through magnetic separation. The magnetic separation is achieved through a novel electrochemical technique. The resulting tailings contain little – or no – sulphides, significantly reducing risk for AMD. The second approach selectively passivates iron sulphides in areas of active AMD. The technique involves micro-encapsulation forming a barrier to oxygen and water, thus suppressing formation of AMD. For the treatment aspect, we propose to use existing mine tailings with alkaline properties. The resulting step change comes in the use of waste to treat waste.

Broader benefit to industry:

Environmental

- Volume reduction of tailings produced

- Reuse of tailings to treat AMD

- Significant reduction of AMD potential in new tailings

Safety

- Improved safety of sites for staff and communities

- Improved control of toxic metals, in particular, arsenic

Economic

- Neutralization of tailings presents increased opportunities for reuse

- Significant reduction of social risk and treatment costs associated with AMD

Recordings of each submission are available to Members only. Please click on the link below to request access to the recordings and nomination form.